By Ian Padley, Tissue Applications Manager, BTG

For tissue paper products, the process of creping is what gives the sheet the required lower density and increased caliper, as well as numerous other desirable properties. This article examines the basic mechanics of the conventional dry-crepe process, the technology which is used for the majority of the world’s tissue manufacture.

By Ian Padley, Tissue Applications Manager, BTG

If you prefer, please download the pdf of the article at this link:

The Basics Of Creping In The Tissue Making Process

1. Introduction

Tissue paper is very often defined by its physical properties, most especially softness or handfeel, (low) density, bulk, caliper or thickness, flexibility or drape and its capacity to absorb water. Tissue paper is distinguished from flat grades of paper because the fibres are in a loosely bound matrix with voids between them, rather than being tightly packed and intimately bound. A tissue sheet will have higher caliper and therefore lower density than a conventional grade of paper of similar basis weight. Contrast old-fashioned tracing paper or thin coloured lightweight paper found in some luxury good packing with tissue, for example.

For a majority of the world’s tissue, the process of creping is what creates this lower density and increase in caliper, as well as the other desirable properties which follow from this. This article will concentrate on conventional dry crepe technologies which comprise the majority of the world’s tissue manufacture, although some aspects of it will be applicable to the manufacture of through air dried (TAD) tissue which a later article will cover.

2. The Mechanism of Crepe

a. Definitions

To understand creping, we need to define some terminology associated with the subject.

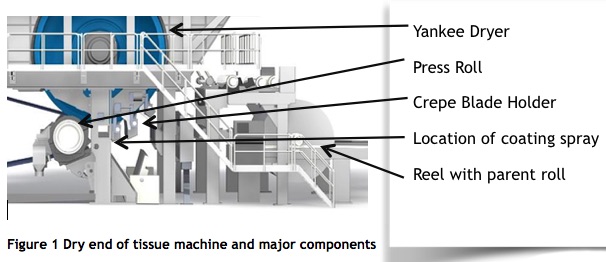

Yankee Cylinder (Yankee dryer) Steam heated rotating (circumference speed ca. 30m/s) pressure vessel usually 14’ to 18’ diameter and slightly wider than the full width of the sheet. It firstly forms the counternip to the press roll or rolls, then dries the sheet by conducted heat (as the sheet is held fast onto it for 2/3 to 3/4 of its circumference) and finally provides the platform upon which the crepe occurs.

Crepe blade Fixed doctor blade running the width of the Yankee in the creping position. This forms the other element of the mechanical components of creping.

Yankee coating A mix of naturally occurring pulp by products (lignins, hemicelluloses) and applied chemicals which form a thin sticky layer on the Yankee face which aids sheet transfer from press to Yankee, and then holds the sheet in place during drying and creping.

The Adhesive strength of the coating defines how hard it sticks the sheet to the Yankee.

Crepe Pocket The zone between crepe blade tip and the Yankee surface where creping takes place.

Blade Holder A mechanical device holding the crepe blade against the Yankee surface.

Crepe ratio The speed differential between the Yankee (uncreped sheet) and the reel (sheet after creping) from where the paper goes to the converting process to make the finished products. Crepe ratio can be calculated three different ways: Yankee speed/Reel speed, (Yankee speed – Reel speed)/Yankee speed, or (Yankee speed – Reel speed)/Reel speed (this is referred to as the ‘Theoretical crepe’, which can be compared to the MD stretch).

Parent roll The large full machine width roll of paper which is the completed production unit from the tissue machine.

b. Debonding Process

In the microsecond before it is creped, the tissue will be at its final dryness, typically 2-6% water content by weight in a thin tightly packed layer of fibres some 7 to 9 fibres deep on the Yankee. The fibres will be attached to each other via hydrogen bonds (H-bonding). One function of creping is to disrupt or break these hydrogen bonds and allow the sheet to expand in the Z-direction so that the 7 to 9 fibre layer becomes partially separated. The energy to disrupt these bonds is imparted by the rotating Yankee to which the sheet is firmly held via the Yankee coating. The moving sheet impacts the stationary crepe blade and the energy transfer takes place, with partial failure of the fibre-fibre H-bonds and fracture of the Yankee coating-Fibre interface.

c. Crepe Process

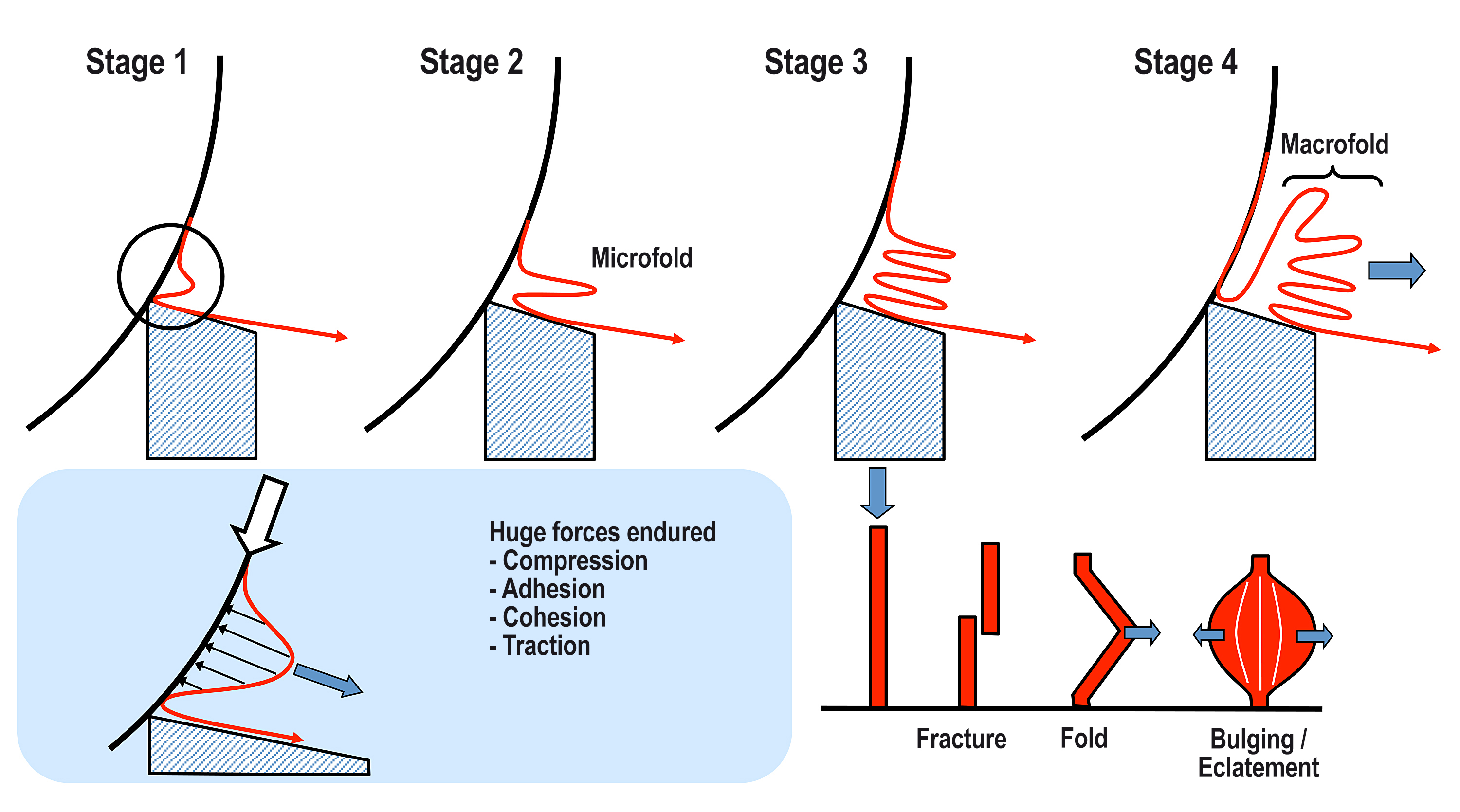

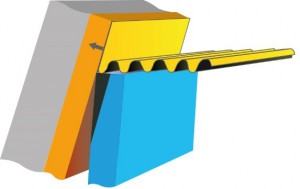

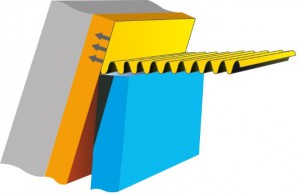

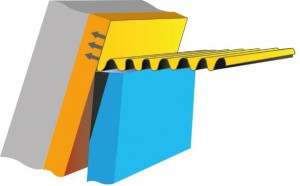

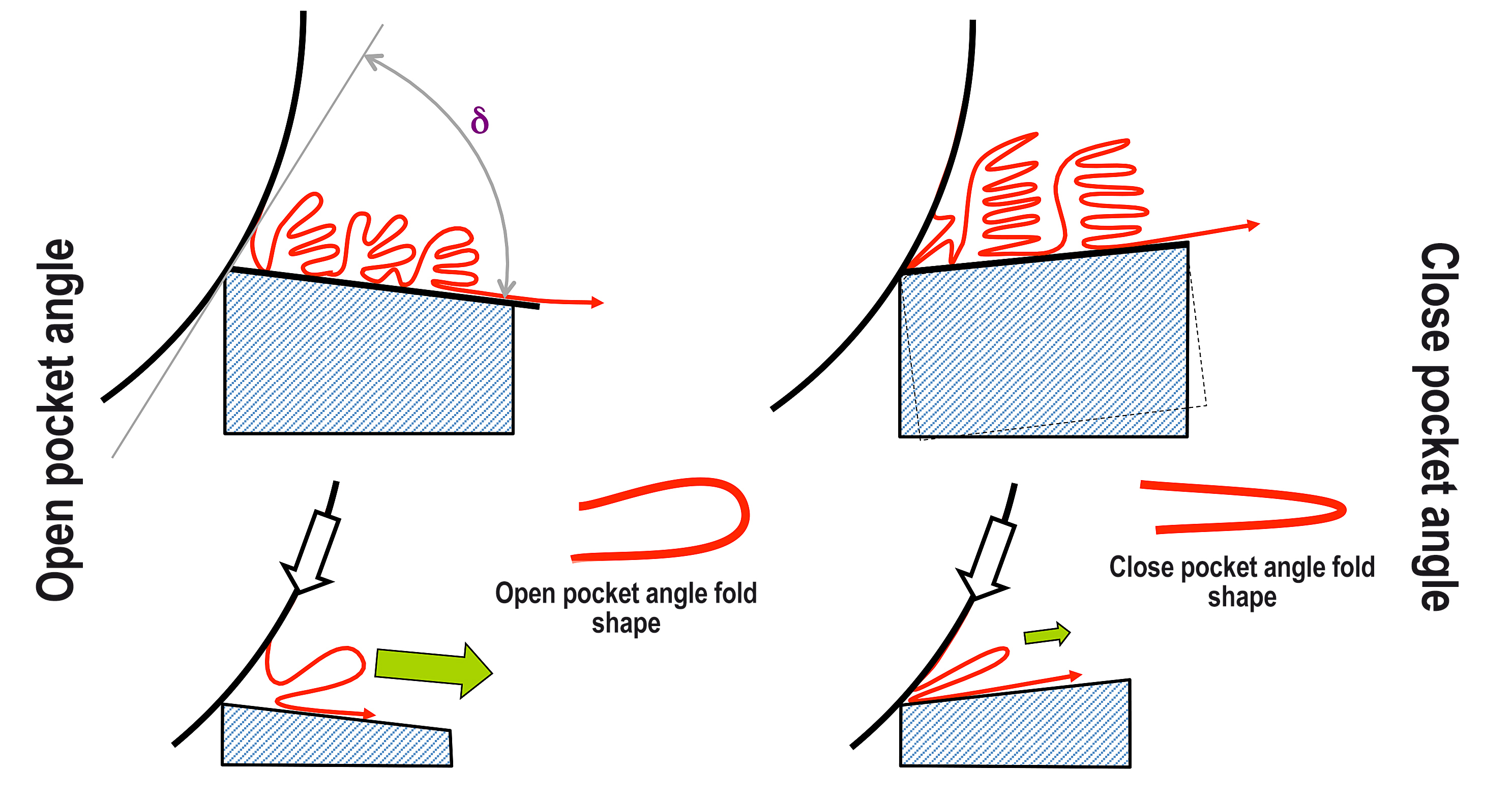

As well as expanding the sheet in the Z direction, some fibres will buckle and bend. Depending upon the adhesive strength, the expanded and buckled sheet will release from the dryer surface for a short distance (Figure 2, stage 1); the stronger the adhesive strength, the shorter this distance will be. Thus a small fold of tissue or crepe is formed before the held sheet re-impacts and the process is restarted. Each fold may be referred to as a crepe bar, which can be examined visually, using lower power microscopes. The crepe bar count might be in the range of 20-40 crepes per cm, meaning the crepe frequency can be in the range of 50-120kHz.

Figure 2 Crepe development and macro/microfold

d. Crepe Ratio

The completed crepes are constantly moving away from the crepe pocket as the sheet is wound up into its parent roll at the reel. The crepe process shortens the length of the sheet whilst increasing its caliper, thus the reel winding up the parent roll will run slower than the Yankee, with a ratio of 15 to 25%

e. Micro and Macrofold

The sheet caliper in expanded first by Z direction H-bond disruption and secondly by the crepe action. However, the crepe itself is not uniform, consisting of large folds (macrofold, figure 2, stage 4) interspersed with many smaller folds (microfold, figure 2, stage 3). More microfolds or microcrepe will generally give a softer feeling, more flexible sheet. However, microfold is very difficult to see with lower power magnification, where we generally only count macrofold. The crepe can also be disrupted in the cross direction (CD crepe) also called bubble crepe from its appearance under low power magnification. This is also desirable for soft feeling tissue.

3. Main Factors Acting Upon Crepe

With a basic understanding of the mechanism of how crepe is formed, we can review some of the major crepe factors and how they influence the final crepe properties and hence tissue sheet properties.

a. Fibre Choice and Management

As said above, the sheet undergoes two transformations, Z-direction H-bond disruption and fibre bending and buckling. It will be apparent therefore that some fibre will be more resistant to these processes than others. Thus tissue makers will choose a mix of short (hardwood) fibres and longer(softwood) fibres commensurate with the final sheet strength properties they desire. The longer softwood fibres will have a good hydrogen bonding potential and add strength and stiffness to the sheet, but can resist the creping action. Softwood fibres with low fibre coarseness (measured as Pulp Coarsness Index or PCI in mg/100m) are preferred with NBSK pulps with a PCI of 13-15 mg/100m used in many premium grades. Hardwood fibres are shorter with a PCI less than 10 mg/100m, and crepe well, but do not make a strong sheet. Thus kitchen towel, where softness is not critical, may contain 70% softwood whereas facial tissue might be as low as 10%, but more typically 20% softwood. Clearly, refining of the fibres is critical (preferably only the softwood), whether mechanical or enzymatic, but in either case, only gentle refining with minimal fibre cutting is needed; an over refined sheet will be stiff and will have low bulk.

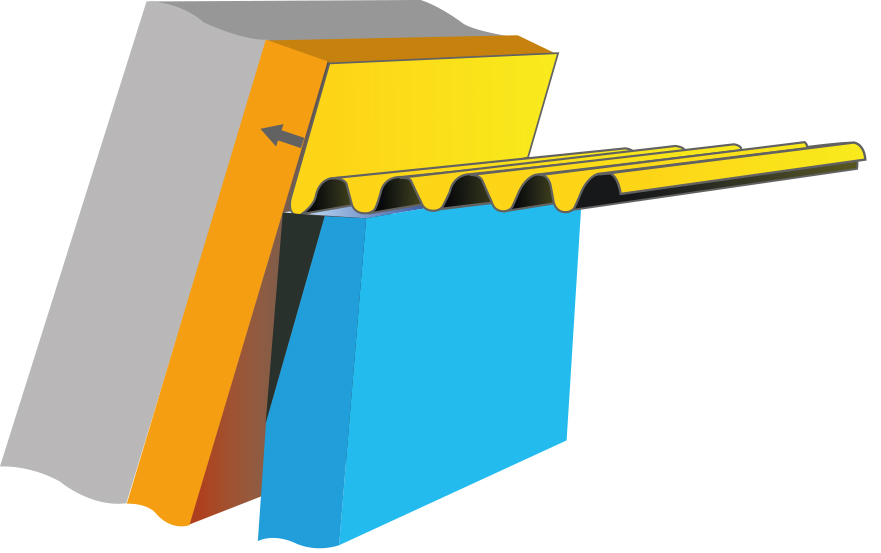

b. Yankee Coating

This is a very critical factor. Other writers will detail the chemical considerations, in this article we are concerned with the generic properties. The applied coating will be a mix of a polymer (either film-forming or thermosetting), typically some kind of polyamine, a release component, often mineral or vegetable oil based and sometimes a modifier, to adjust the film rheology. These are sprayed onto the Yankee as a mix in water, around a 1% concentration, about 1 m before the sheet transfer onto the Yankee at the press. In this 1m, the Yankee will evaporate most of the water carrier and the tacky film will pick up the wet sheet from the press. The polymer component will hold the sheet firmly as it dries, ready to resist the creping pressure. To understand how the tissue maker selects and controls these chemicals, we can categorise three main types of coating condition:

i. Soft, low adhesive coating

This will give a coarse crepe with high crepe amplitude and low frequency. The adhesive layer will fracture easily, this giving a large bulky crepe structure. This would be typical for machines making a hand drying towel grade, for example.

ii. Hard, high adhesive coating

This will give a very fine crepe, low amplitude and high frequency. The fracture span of the adhesive will be very small. This is typical for machines making low caliper but very smooth feeling facial or hanky tissue grades.

iii. Soft, high adhesive coating

This will give both high crepe frequency and amplitude and is characterised by a high proportion of microcrepe in the crepe structure. It is thought that the crepe blade tip penetrates more into the coating in this variant and it is this which creates the more bulky structure. This type of crepe characterises soft and bulky tissue grades such as premium toilet tissue.

c. Sheet Drying

Increasing the Yankee temperature will increase the adhesive strength of the coating, to a certain degree, and will normally improve bulk and handfeel. Several super-premium grades are made at very low moistures. However, too much Yankee drying will also harden the coating, which eventually works against the bulkiest crepe creation. Therefore a slight bias towards hood drying will generally favour the highest softness.

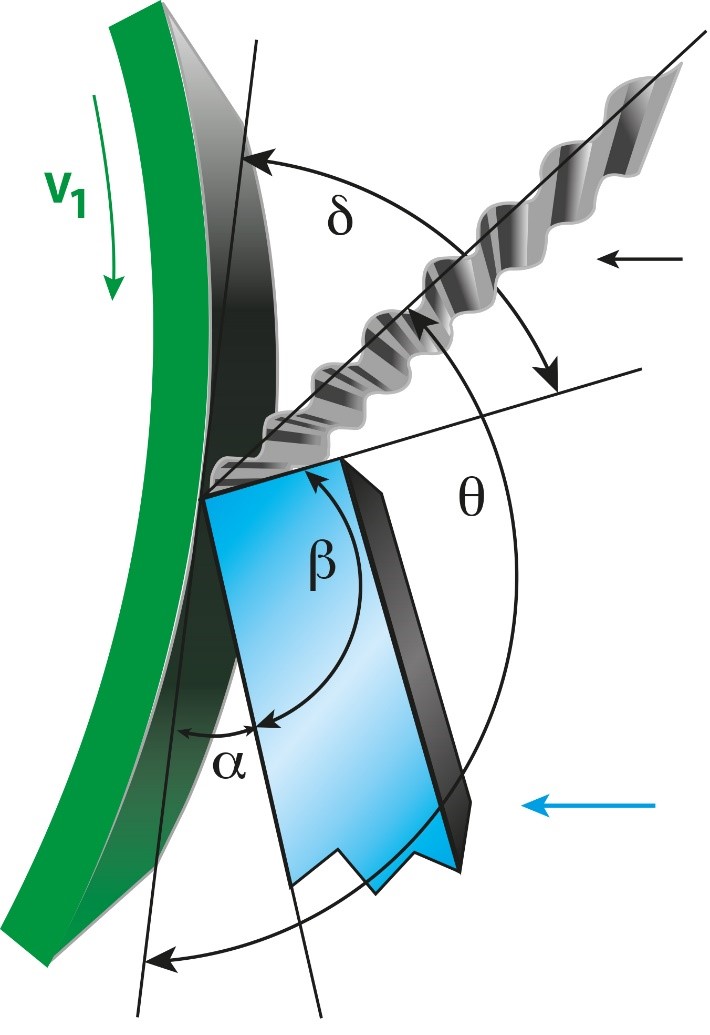

d. Crepe Pocket Geometry

As shown in Figure 6, this will be the other critical factor. The important angles are the pocket angle, ɗ, comprised of the blade bevel angle ß, and blade holder sliding wear angle, α, combination. The blade free height or stickout also influences this due to blade deflection.

Figure 6 Essential angles in crepe pocket

The blade sliding wear angle, α, is also influenced by the delection or bending of the blade, such that sliding wear angle ɑ comprises the actual blade holder angle (sometimes called blade set up angle) minus the deflection. The final sliding wear angle is constrained in two ways. If it is too low (less than 15 ˚ to the tangent of the Yankee surface for example) then its ability to detach the sheet is impaired and the sheet can bypass or plug the blade leading to a web-break. If the angle is too high (much over 20˚) then it imparts too much friction against the Yankee and in the long term Yankee wear or damage from chattermarks becomes a concern. Thus a blade holder angle of 17 to 19˚ is typical. In order to achieve a more open pocket angle therefore, the blade can be bevelled, with bevels up to 60˚. The more open pocket (>90˚) tends to give a lower bulk and more close crepe (higher crepe frequency) structure, and is typical for high softness tissue grades. In fact, as shown in figure 7, the amplitude of macrofold is decreased with a more open pocket angle, and the reverse is true for a closed pocket, where higher bulk and lower handfeel can result. The blade stickout will determine the fine tuning of the pocket angle as blade deflection can open the pocket by up to 3˚ if the stickout is increased. However, a high stickout can also allow the blade to vibrate more and can also lead to bypassing, so a 20-25mm stickout is a common best practice with many types of blade holder.

Figure 7 Impact of pocket angle closure increasing macrofold

e. Crepe Blade Material

The final factor is crepe blade material. The use of high performance (HP) crepe blades, typically ceramic or carbide materials, has become increasingly common as they impart certain advantages to the tissue maker looking to improve quality and productivity:

i. Slower sliding wear rate

The sliding wear area of the HP blade develops much more slowly. The sliding wear pad of a blade reduces its specific loading pressure and thus ability to doctor the sheet and coating. The HP blade reduces the need to change the blade (and lose some minutes of production) as frequently.

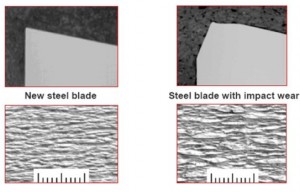

ii. Slower impact wear rate

Impact wear of the crepe blade closes the crepe pocket angle and reduces sheet softness by creating a more coarse crepe. Impact wear develops much more slowly with HP blades.

Figure 8 Impact of steel blade wear on crepe structure. New steel blade on left, Steel blade with Impact Wear on right

iii. Smoother surface

The ceramic or carbide creping surface of an HP blade is very smooth, and this will normally give a finer crepe and superior handfeel to an equivalent angle steel blade. Bulk may be less, but a lower bevel angle can generally be run with an HP blade to compensate for this with no detriment to tissue softness.

4. Summary

In summary, we can see that creping is a complex interaction of many factors. The basic mechanism is a disruption of the inter-fibre H-bonding, distortion of the fibres themselves and formation of micro and macrofolds in the tissue substrate. The most critical factors for the tissuemaker to consider are the selection and management of fibres, selection and control of Yankee coating chemistry, including drying strategy, crepe pocket geometry and choice of crepe blade material.

Several of these aspects will be covered in more detail in later articles.

Please feel free to share this content. Click on your favorite social media below. Thank you!

Comments are closed.